Understanding CO2:

North Dakota is known for, and extremely proud of its agriculture and energy production. As federal regulations continue to impose stricter standards on the oil, gas, biofuel, and coal industries, the state has seen a drastic increase in demand across all energy sectors for capturing, using, and permanently storing carbon dioxide (CO2) deep underground.

The Science of CO2

CO2, not to be confused with carbon monoxide (CO), is a non-flammable, non-explosive, naturally occurring gas. It is exhaled by humans every time you breathe, and is used in hundreds of products including soda, dry ice and fire extinguishers; and is a necessary component in plant growth.

The North Dakota Advantage

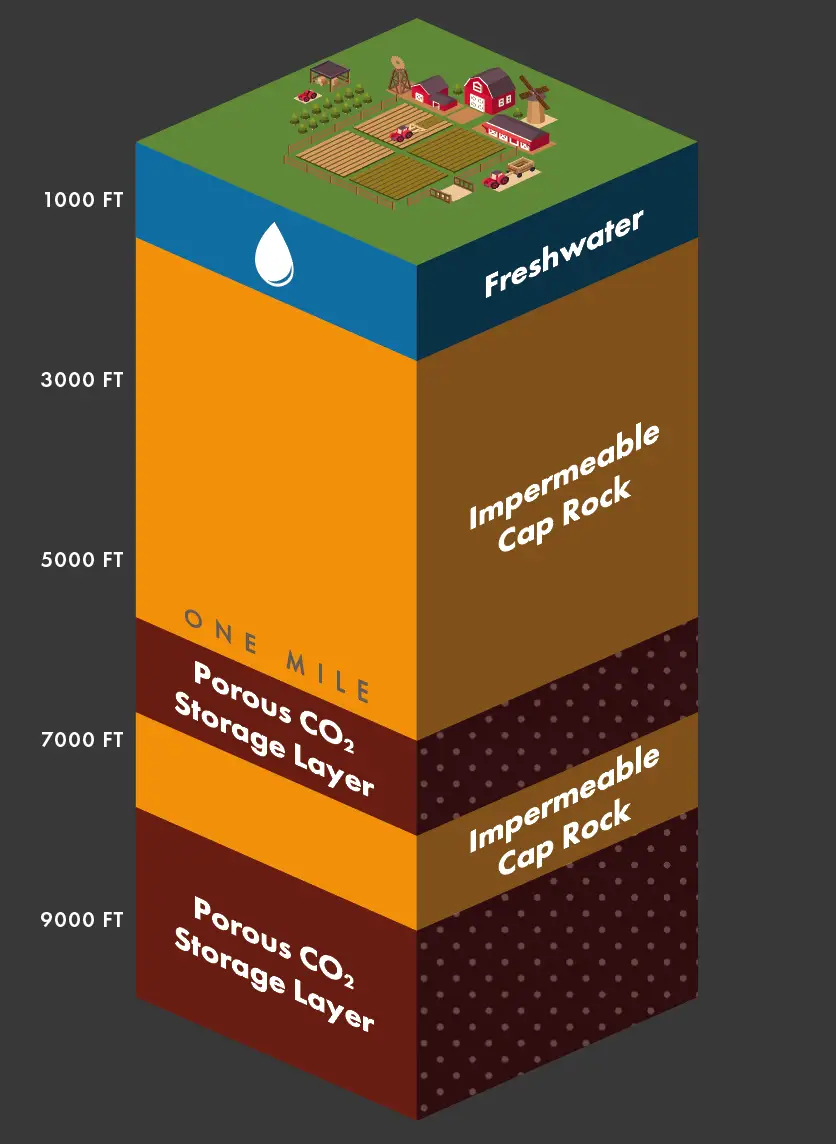

North Dakota’s unique geology – the same underground rock formations that make oil and gas production so successful – is perfectly suited for the permanent, safe storage of CO2 nearly a mile or more below the surface in deep, deep rock layers. Learn more about the science of CO2</sub >.

CO2 also has the potential to help exponentially extend the life of North Dakota oil fields through enhanced oil recovery (EOR). Learn more about the North Dakota Advantage

A Long History With CO2

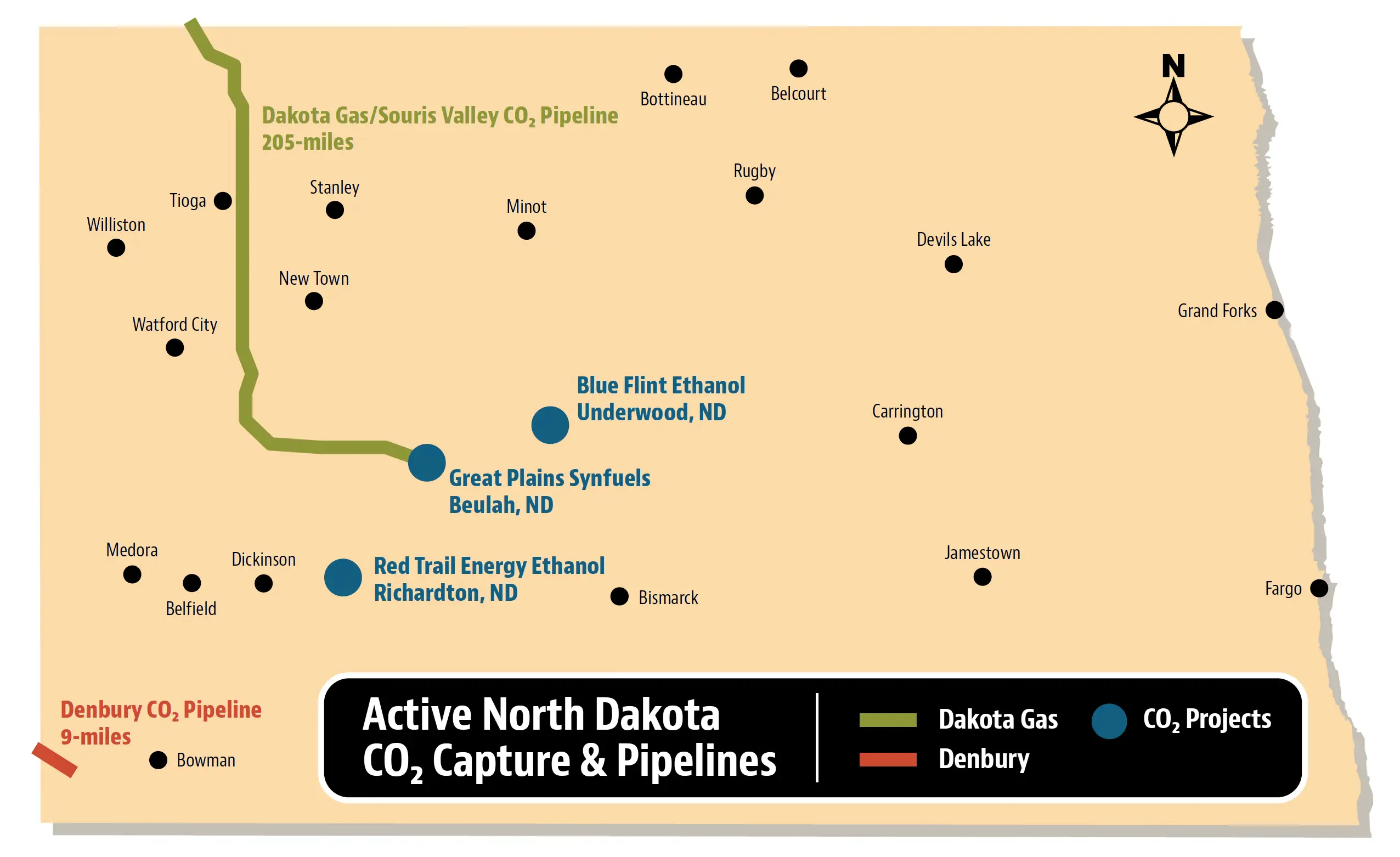

While carbon capture is currently making the headlines – it’s not new. Underground CO2 injection for enhanced oil recovery (EOR) began in western Texas in 1972. Decades of data has helped us understand how CO₂ behaves deep underground, and how to safely transport it through pipelines. US Carbon Capture Activity and Project Map North Dakota, with the guidance of the University of North Dakota Energy & Environmental Research Center (EERC), has also been at the forefront of studying and implementing carbon injection, utilization, and storage initiatives for more than 20 years. Today, millions of metric tons of CO₂ are safely transported across the country through 5,000+ miles of pipeline – including nearly 200 miles in North Dakota.Red Trail Energy Ethanol Plant, Richardton, ND

Began operations on June 16, 2022, as the first commercial-scale CO2 capture and storage project in the state. The plant captures and stores up to 180,000 metric tons of CO2 annually. Learn more (opens in new window)Blue Flint Ethanol, Underwood, ND

Harvestone Low Carbon Solutions began operations of the second commercial-scale CO2 capture and storage project in North Dakota on October 28, 2023. The plant captures and stores up to 220,000 metric tons of CO2 annually. Learn more (opens in new window)Great Plains Synfuels Plant, Beulah, ND

Since the early 2000s, the Dakota Gasification Company (DGC) has used pipelines to send up to 2 million metric tons of CO2 to Saskatchewan, Canada annually for enhanced oil recovery (EOR). On February 4, 2024, the DGC Beulah Broom Creek Storage Facility began onsite CO2 capture and storage of up to 2.7 million metric tons of CO2 annually. Learn more (opens in new window)Dakota Gas/Souris Valley Pipeline

This 205-mile CO2 pipeline runs from the Dakota Gasification Plant near Beulah, northwest past Tioga, and into Saskatchewan, Canada. It has been transporting up to 2 million metric tons of CO2 annually for enhanced oil recovery (EOR) for nearly 25 years. Learn more (opens in new window)Denbury/ExxonMobile Pipeline

The final 9 miles of this CO2 pipeline, which originates in Wyoming, has delivered CO2 to the oilfields in the Bowman area for enhanced oil recovery since 2022. Learn more (opens in new window)CO2 Storage Safety

CO2 Pipelines

CO2 pipelines have been operating safely in the United States for more than 50 years – with more than 50 operating pipelines spanning over 5,000 miles today. These pipelines transport millions of metric tons of CO2 annually across entire regions of the country.

Unlike natural gas and liquid petroleum – which are transported through millions of miles of pipelines across the U.S. – CO2 is not flammable or explosive. These pipelines have stringent regulations, monitoring, and mitigation requirements.

Pipelines are also designed to safely operate under the pressures required to effectively transport CO2. For example, the Dakota Gas/Souris Valley CO2 Pipeline, which has been in operation in North Dakota for nearly 25 years, transports CO2 at over 2000 PSI. That pipeline is built for a maximum operating pressure of up to 2700 PSI. Before any CO2 is transported via pipeline, the pipes are hydrostatically tested, which means they are filled with fresh water or an inert gas at a pressure 125% of the maximum operating pressure to ensure their structural integrity.

While prolonged exposure to high concentrations of CO2 can be hazardous, the gas typically quickly evaporates into the air. In the unlikely event of a leak, pipeline systems are designed to automatically shutdown, ceasing all operations until the cause is determined and repaired, and a reporting process through North Dakota’s Unified Spill Reporting System is triggered.

CO2 Safeguards

Safety of CO2 transport and storage is ensured through rigorous site selection, extensive monitoring, and regulatory oversight. North Dakota requires extensive review and approval of plans to operate pipeline and storage facilities and inject CO2. All CO2 storage projects must include:

- Class VI well construction with surface casing/cementing protecting water resources, cementing from the surface to the injection point, and corrosion-resistant casing and cement

- Next-Level Monitoring: multi-layer, multi-protection, multi-action 24/7/365

- Operational monitoring for temperature and pressure changes that could indicate early anomalies

- Leak detection and alerts

- Deep underground monitoring to ensure that the CO₂ remains securely in the storage zone

- Surface and near surface monitoring to ensure no environmental effects

- Surface water, groundwater and soil regular testing

- Shutoff requirements

- Risk assessment and mitigation including comprehensive manuals at each site and control center with actions for various scenarios

- Liability on storage facility owner, not landowner

- Post injection site care and closure

- Continuous monitoring after injection ends, until it is demonstrated that CO2 stops moving (at least 10 years)

CO₂ storage facility operators must have the proper financial instruments and ability in place to cover the cost of any necessary corrective action, injection well plugging, post-injection site care/facility closure, and emergency and remedial response. These instruments must remain in place until the CO₂ storage facility is approved for closure.

What Happened in Satartia, Mississippi?

In February 2020, a CO2 pipeline near the community of Satartia, Mississippi was severed by a landslide, releasing high concentrations of CO2 into the atmosphere. This incident resulted in a thorough investigation by the Pipeline and Hazardous Materials Safety Administration (PHMSA). PHMSA identified several factors that led to this pipeline rupture, and ultimately cited the pipeline operator for violating multiple existing regulations. Thankfully, there were no fatalities as a result of this incident.

Contributing factors to this failure included:

- The soil where the pipeline was installed was unstable, and susceptible to movement from high rainfall.

- The rupture followed heavy rains (7.5 to 13.5 inches above average) that resulted in a landslide, rupturing the pipeline as the ground shifted.

- When CO2 from pipelines is released into the air, it naturally vaporizes and dissipates. Local weather conditions, lack of wind, and the density and volume of CO2 released slowed the dissipation of the CO2 back into the atmosphere.

- The pipeline operator’s dispersion model underestimated the potential affected area in the event of a CO2 release.

- The pipeline operator did not adequately inform local emergency responders prior to or during the incident.

- The pipeline did not contain pure CO2.

One misconception about the Satartia pipeline incident is that the pipeline “exploded.” CO2 is non-flammable, and non-explosive, so no explosion occurred. Rather, the pipeline rupture (caused by a landslide) resulted in a phenomenon known as “explosive decompression.” Explosive decompression in pipelines happens when a pipe that carries gas or liquid breaks very quickly. Think about blowing up a balloon and then popping it with a pin. The air rushes out quickly and makes loud noise from the change in pressure. When a pressurized pipeline suddenly breaks, the gas or liquid inside escapes just as quickly, causing a powerful rush disturbing the ground immediately around the break point. In Satartia, the liquid CO2 in the pipeline immediately transitioned back to a gas with some residual “dry ice” in the immediate area.

This was the first such “worst-case scenario” failure of a CO2 pipeline among the 5,300 miles of CO2 pipeline currently in service across the U.S., and resulted from several unique factors combined with failure by the pipeline operator to uphold PHMSA standards. Historically, PHMSA requirements have a safety record outperforming the safety standards of both rail and truck transport.

Read the PHMSA Report on the Satartia, Mississippi pipeline incident »

About This Initiative

Additional Resources

- North Dakota Industrial Commission

- North Dakota Department of Mineral Resources

- Energy & Environmental Research Center (EERC) – University of North Dakota

- PCOR Partnership

- Pipeline and Hazardous Materials Safety Administration (PHMSA)

- US Carbon Capture Activity and Project Map

- Lignite Energy Council

- North Dakota Petroleum Council

- North Dakota Ethanol Council

- Economic Development Association of North Dakota (EDND)

- North Dakota State University (NDSU) Extension

- North Dakota Department of Commerce

- Western Dakota Energy Association